Mini Rotary Evaporators

Other manufacturers don’t give your lab the precision you need to do your best work.

If you’re in process development, method development, or doing basic R&D, most rotary evaporators on the market aren’t actually built for you.

Unique R&D Precision

Test New SOPs Quickly

Program RAMPS Easily

Widest Rotation Range on the Market

Fastest Rotation Available

Reduce Steps After Drying

Unique R&D Precision

Widest Rotation Range on the Market

Test New SOPs Quickly

Fastest Rotation Available

Program RAMPS Easily

Reduce Steps After Drying

Most rotary evaporators are built to help you follow a recipe. So what if your job is testing new recipes?

Yamato rotary evaporators are built specifically for process development, and can naturally be used in applications where other lab-scale rotary evaporators are.

Most rotary evaporators are built to help you follow a recipe. So what if your job is testing new recipes?

Yamato rotary evaporators are built specifically for process development, and can naturally be used in applications where other lab-scale rotary evaporators are.

What makes them best mini rotary evaporators for process development?

Features that give you more control as you explore.

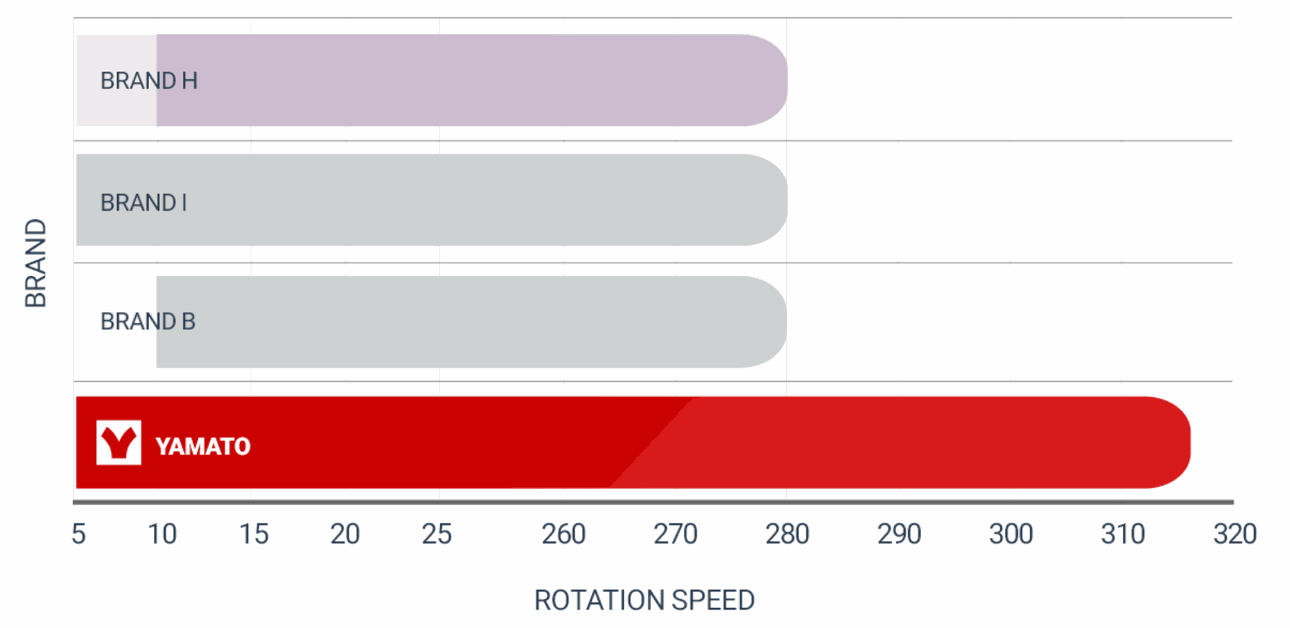

- You can test your process with a greater range of speeds than any other rotovaps on the market. With a rotation as gentle as 5 rpms or as aggressive as 315 rpms.

- You can program your test method or SOP into the system and walk away. Rotate forward at 5 rpms for 30 seconds. Reverse at 5 rpms for 30 seconds.

- You get more detailed information in real time on your display, so it’s easy to track what you’re doing at a glance.

How do other mini rotary evaporator manufacturers compare?

Most other manufacturers don’t offer the precision you need.

Yamato REV/RE202 Rotary Evaporators offer the widest range of rotation speed on the market.

"Cut solvent drying time by 50%. More reproducible sample prep."

REV202M Rotary Evaporator in Applied Chemistry

Application: Prepare catalysts and adsorbents as carriers for active ingredients

Masato Takeuchi

PhD, Associate Professor

Osaka Metropolitan University, Japan

Applied Chemistry, Physical Chemistry Research

Masato Takeuchi

PhD, Associate Professor

Osaka Metropolitan University, Japan

Applied Chemistry, Physical Chemistry Research

“We use infrared spectroscopy to do surface analysis of catalysts, chemical heat storage materials, and adsorbents.

When we load active ingredients onto catalysts and adsorbents, we use aqueous solutions as solvents, which we need to remove at a later stage.

Drying high boiling point solvents, like water, used to take us 4 hours.”

Save 2 hours when drying high-boiling point solvents

“With the vacuum controller that comes with the Yamato rotary evaporator, internal pressure is adjusted automatically to optimize the drying process. This helped us cut the solvent evaporating time by 50%.

Not only does this speed up our workflow, the Yamato rotary evaporator gives us higher reproducibility in the physical properties of our samples.”

No bumping, more walk-away time

“We saw the Science YouTuber Genki Ichioka using the REV202M to concentrate extracted components, and we were immediately impressed by how good the rotary evaporator managed internal pressure to prevent solvent bumping.

This level of precise control during solvent evaporation under reduced pressure conditions is exactly what our lab needs."

“Minimized bumping. Easy operation”

REV202M Rotary Evaporator in Reaction Control Chemistry

Application: Solvent removal following chemical reactions and after column purification

Kosuke Osawa

Assistant Professor

Tohoku University, Japan

Graduate School of Pharmaceutical Sciences Heterocyclic Chemistry

Kosuke Osawa

Assistant Professor

Tohoku University, Japan

Graduate School of Pharmaceutical Sciences Heterocyclic Chemistry

“Our research is primarily on middle-molecular compounds, like cyclic peptides. Our main focus is on the multi-step synthesis of natural products with unique biological activities.

We use rotary evaporators to remove solvents, especially during large-scale syntheses.”

Simplify solvent removal with Yamato rotary evaporators

“I’ve been on the look out for evaporators with vacuum controllers to simplify solvent removal. The REV202 minimize bumping, even when removing large amounts of solvent, which means less hands-on adjustment during concentration phase.

This frees up technicians to do other tasks and increases our overall process efficiency.”

More lab efficiency with Yamato REV rotary evaporator

“Ease of use is also a major plus. Students new to our lab can operate the Yamato instrument effortlessly.”

Get better yield and more lab efficiency with VR Vacuum Controller

VR102S Vacuum evaporator controller for existing rotary evaporators

Eiko Sugiyama

Professor

The University of Nagano, Japan

Department of Food and Health Sciences

Eiko Sugiyama

Professor

The University of Nagano, Japan

Department of Food and Health Sciences

Our biggest headache: rapid boiling when concentrating liquid extracts

“Our research requires extracting lipids from local vegetables and analyzing the components of phospholipids and glycolipids.

Since vegetables are low in lipids, we are often dealing with a large quantity of samples with a high volume of liquid extracts. Rotary evaporators are then used for concentration and separation.

Bumping is our biggest headache when using a rotary evaporator to produce concentrates. We have to manually open and close the cock to prevent rapid boiling, which is a difficult and labor-intensive task. I know many labs facing the same problem.”

Wireless RV102S Vacuum Controller to minimize bumping

“In the vacuum controller's gradient mode*, I can gradually adjust the degree of vacuum to the target pressure and obtain excellent yield.

The Yamato Vacuum Controller worked smoothly with our lab’s rotary evaporator, and I’m very happy about the upgrade.

This improves our lab efficiency significantly, as our operators can now work on other tasks while the rotary evaporator is running and not worry about bumping.”

*To minimize bumping, the VR102S manages the rate of pressure reduction, gradually decreasing pressure from a specified point in the depressurization process to the target pressure. Both the starting pressure for this controlled, gradient operation and its duration are automatically determined based on the set target pressure.

Does precision matter in your lab?

Did you know some rotary evaporators are built specifically for R&D and process development?

Some manufacturers just scale down their large-capacity rotovaps and repackage them as process development instruments. But they don't have the features to actually support your work.

Our experts put together a guide that can help you get what you need for the process or method you're testing.

No spin. Just the facts you need to make an informed decision.

Make your vacuum evaporator process more efficient

Program your test method or SOP into the mini rotary evaporator and walk away to prep or observe other work.

Programming ramps or other processes saves hours of process micromanagement every week.

An example of that might be…

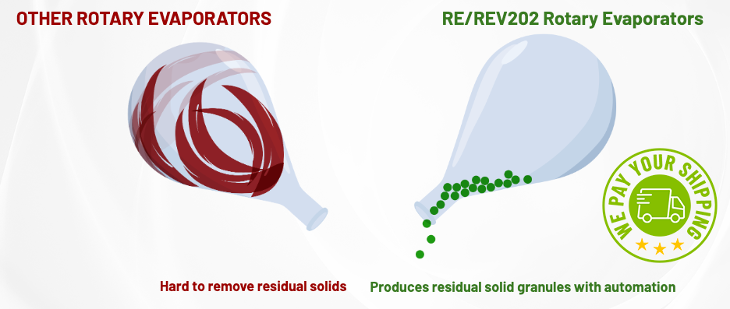

Making it easier to remove residual solids after distillation

Set your rotary evaporator to create dry granules rather than a large chunk of residual solids by automating direction and rotation speed changes.

This process could look something like…

- Set rotation speed to 15 rpms and forward rotation for 15 seconds

- Rotate reverse at 15 rpms for 15 seconds.

- Repeat for 40 minutes

Easy residual solid removal after distillation

It takes about 20 seconds to program rotation direction and speed with the REV202 rotary evaporator.

You save hours of process micromanagement.

And it makes removing your residual solids 10X easier.

Got residual solids stuck on glassware after distillation?

You waste time processing the residual for analysis, not to mention cleaning glassware.

Get everything you need in one location

- Your rotary evaporator

- Your water bath

- Your water circulator

- Your vacuum pump

“It was an easy purchase. The price was about 20% better than any other quote I received, and the quality is equal to our existing system from another manufacturer. I’m surprised I don’t see more Yamato equipment in labs around campus.”

Linda Earle

Chemistry Lab Director

Does precision matter to you?

The big name rotary evaporator manufacturers don’t give you the precision you need.

And they put a strain on your budget.

Someone in your lab cares how far that budget stretches.

Get the precision you need at a cost that puts a smile on your manager’s face.

Products

|

|