Laboratory Spray Dryer

Reduce budget waste, sample waste, and risk in your spray drying process with the worlds most precise laboratory spray dryer.

Yamato lab spray dryers objectively outperform other manufacturers in every way that matters in your workplace.

You’ll save budget, waste or lose less sample, spend less on repairs and increase process uptime, create better products, and do better work.

Reduce Drying

Costs in R&D

Industry’s #1 R&D Spray Dryer

Eliminate Most Manual

Drying Steps

Smallest Footprint Available

Develop High

Profit Processes

Optimize SOPs Quickly

Reduce Drying Costs in R&D

Industry’s #1 R&D Spray Dryer

Eliminate Most Manual

Drying Steps

Smallest Footprint Available

Develop High Profit Processes

Optimize SOPs Quickly

An Introduction to Spray Dryer

Can your sample/solution be spray dried successfully?

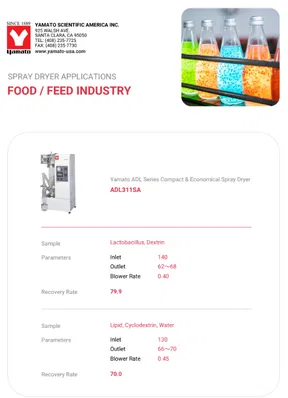

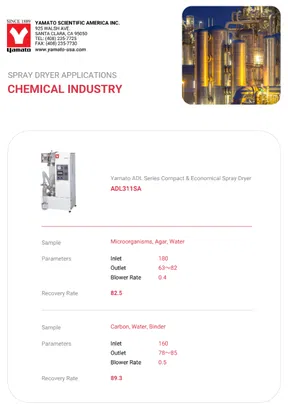

Here’s a quick reference for sample types and the parameters used to successfully spray dry them. These are real, verified samples used in labs today.

In Pharma

In Food

In Chemicals

Spray dryer DL410 in food and beverage

Application: Emulsions

User Insights:

Why customers choose Yamato spray drying equipment?

“We selected this spray dryer over other options because 90% yield could be achieved at a price significantly cheaper than other similarly sized spray dryers."

The equipment additionally had a much shorter lead time than any other manufacturer.

Additionally, one of the benefits other users might not think about until after purchasing is that the operator can see the nozzle spray in the main chamber.

Here’s exactly what helped us achieve our goals:

- Dryer design leads to optimal yields (product pulled from the bottom of the main chamber as opposed to outlet arm)

- Evaporation capacity sized appropriately to our formulation’s total solids content

- Ability to spray dry a formulation that contains a solvent

- Cyclone optimally sized for target particle size and yields

- Small footprint

Why does this user recommend Yamato spray dryers?

“The dryer design is optimal. It allows us to achieve above average yields for spray drying. And Yamato’s customer service over the past 2 years has been excellent. Any questions have been answered in detail by Yamato’s technical service within 24 hours (usually much

quicker). Their reps are very thorough when troubleshooting issues and offer to work with customers over video chat.”

Lab spray dryer ADL311SA and GAS410 solvent recovery system in university labs

Application: Spray drying of drug infused polymer

The lab was working on producing a non-sticky spray-dried powder from aqueous solutions of hygroscopic materials.

The source solution would jam up the spray nozzle on most spray dryers quickly, and the operator would spend more time cleaning the nozzle through the day than creating powder.

User Insights:

Why customers choose Yamato spray drying machine?

“Fortunately, the pulse jet switch on the touch panel and the plunger of the upper nozzle allow many hours of run time without disassembling and cleaning all the parts of the nozzle”

“The operator also uses Yamato’s solvent recovery system GAS410 along with the ADL311S spray dryer, “which allows us to spray aqueous, alcoholic, and hydroalcoholic solutions safely.”

“One of the features we really like is the specimen tray. Rather than forcing us to use a specific specimen container, we can easily place any beaker or sample container with a large volume on the specimen tray”

Why does this user recommend Yamato spray dryers?

“I would recommend this product because the unit is easy to operate, reliable, and Yamato’s customer service is good.”

Spray dryer DL410 in metals, minerals & mining

Application: Amorphous silica production

User Insights:

Why customers make Yamato their spray dryer manufacturer?

“We were looking for a product to produce zinc sulfate mono hydrate powder from aqueous (non-organic solvent) solution containing about 0.5 kg zinc sulfate per liter. Wanted to produce about 5 kg per day (~10 L/day solution) with particle size of at least 100 microns. Wanted to run the unit 24 hours a day.”

“For us, the best feature might be the needle knocker/nozzle blower which can allow many hours of run time without cleaning. We installed a custom 5L collection jar equipped with band heater that allows us to spray dry 1kg at a time without the need to cool the unit and empty the jar. So the ability to run for a long time without cleaning is very valuable.”

Why does this user recommend Yamato spray dryers?

“I recommend this product because the unit is reliable, and customer service is good.”

Spray dryer GB210A and GAS410 solvent recovery system in preclinical drug product manufacturing

Application: Formation of enabled formulations to support preclinical development

The user needed a closed loop spray dryer to allow for spraying of organic solvent based solutions. The spray dryer needed to support small scale pilot batches for initial characterization and larger scale production to support in vivo studies.

User Insights:

Why customers choose Yamato spray drying equipment?

“We invested in the GB210A and GAS410 to support preclinical development of our lead pharmaceutical candidates. The simplicity, robustness, and cost all contributed to our decision to purchase this spray dryer setup. In addition, the option to perform fluid bed drying on the same equipment is great to have for future formulation research.”

“We have used a technique to spray directly into small vials and jars, increasing the yield, especially for small scale batches”

Why does this user recommend Yamato spray dryers?

“Product support has been especially great. The team is very responsive and flexible in trying to help their customers.”

How do Yamato mini spray dryers help me reduce budget and sample waste?

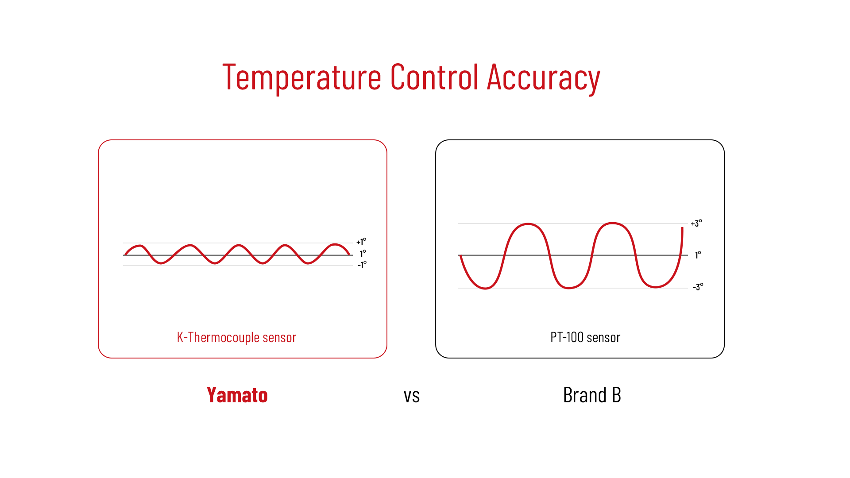

Let’s start with the temperature sensor.

We use a K-Thermocouple sensor (vs other brands using a PT-100 sensor).

That gives you temperature control more accurate and stable than the brands using a PT-100. That includes the big brand you’re familiar with.

Why does that matter?

Temperature swings = risk and waste in your lab. So if you want to avoid risk and waste in your spray drying workflow, this is objectively the best way.

Find the mini spray dryer model best suited for your work here

Simple, but impactful innovations in a spray dryer machine

In every other spray dryer machine you’ve used, the drying chamber is secured by hand with screws.

Your Yamato GB210A has an electric lift (at no additional cost) and requires no screws.

How does this help my lab?

Lab technicians have to manually remove the spray drying chamber repeatedly. It takes time and multiple staff to complete this manual operation with other manufacturers’ spray dryers.

This takes lab staff away from other tasks.

This adds downtime to the spray drying workflow, as well as other workflows in the lab.

This increases risk of the drying chamber slipping, breaking, and causing all kidneys of trouble.

Removing and reinstalling the Yamato drying chamber is a 1-person job that takes a few seconds.

Might want to experiment with granulation in the future?

A simple glassware swap allows your business to experiment with granulation and encapsulation using a fluid bed.

This is not available from any other manufacturer.

How does this help my lab?

It would be an additional investment of > $100k to get an additional mini spray dryer from another manufacturer purpose-built for granulation.

Your lab can spend that money more prudently.

Click here to learn more about prudent choices for your budget

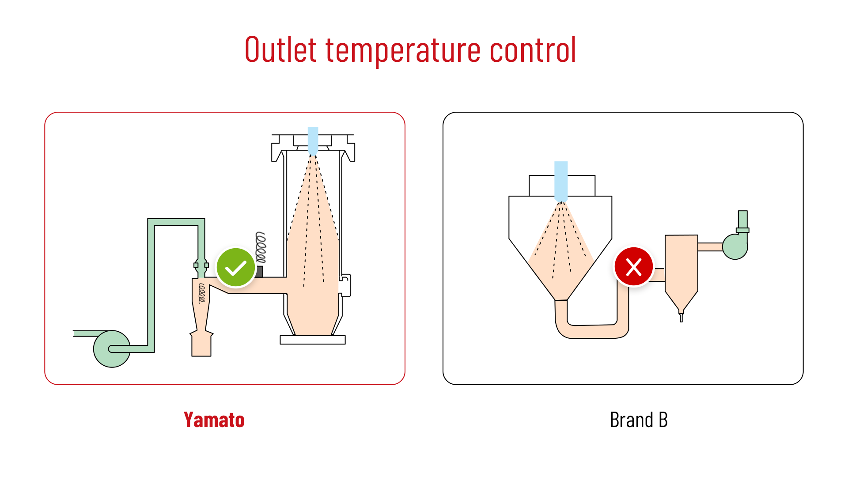

Get more spraydry temperature control options

Wait. There are temperature control options?

All mini spray dryers let you control the inlet temperature.

Only Yamato spray dryers let you also control the outlet temperature.

Why do you care?

Because the temperature upon output can drop drastically, impacting the quality of your powder.

Temperature-sensitive samples react better when they’re at the right temperature at the end of the process.

Outlet temperature control just means there’s less risk in your process.

Learn more about mini spray dryers that reduce your risk

This is getting long-winded. Here are 3 more at a rapid pace

| Evaporation capacity | Sample protection | User protection |

|---|---|---|

| Brand B: 1.0 L/h h3O | It’s an add-on cost from brand B. | Other manufacturers treat safety as an accessory (with an added cost) |

| Yamato: 1.5 L/h h3O | It’s standard on your Yamato mini spray dryer. | Your Yamato spray dryer is delivered with a safety cover as standard with no additional cost. |

| Why do you care? | Why do you care? | Why do you care? |

| Allows your lab to process 50% more powder in a day. | Because cost control is part of your job | You don’t really have to ask about this one, right? |

There’s more, but if you read this far, it’s about time you contacted us. Ask about how the peristaltic pump helps you save budget, reduce risk, and pare down waste.

Contact us today to confirm the right model for your application

Commercial Food Products

Spray dryers were used widely during the Second World War to produce milk powder. Hence, it is no surprise that the largest market for lab spray dryers nowadays is in the food industry particularly in powdered milk and instant coffee production.

From milk production, the use of spray drying technology has extended to the production of powdered varieties of coffee, algae, gum arabic, protein hydrolysates, yeast extract, starches, and non-dairy creamers to name a few.

You can now rapidly create agglomerates or powder from liquids such as emulsions, suspensions, and solutions since spray dryers are fully-automated and continuous. Moreover, spray drying equipment such as the ADL311SA—a Compact & Economical Spray Dryer by Yamato—are highly suitable for drying both heat-resistant and heat-sensitive foods, allowing shorter residence time with no oxidation and minimal moisture remaining.

Spray drying is also used for encapsulating active substances, homogenizing these into slurries or emulsions before drying. By encapsulating food products, you get to protect your product from heat degradation and therefore improve final product functionality.

Pharmaceutical Products

Not all medical dosages are soluble. Hence, spray drying technology affords the pharmaceutical industry an economical and fast alternative to converting liquid feed into powdered medications and additives such as extracts, infusions, inorganic medicinal salts, vitamin C, and adrenaline.

Since the 1940s, the use of spray drying equipment in pharmaceuticals has advanced from simple drying methods to sophisticated processes such as the production of excipients like ointment bases and preservatives and the isolation of active ingredients that are either hard-to-crystallize or heat-sensitive.

Needless to say, spray drying is an ideal process for those requiring precise attributes especially in the morphology, stability, and particle size of your pharmaceutical products.

In just a single continuous process, you get to convert liquid feedstock into a well-defined powder and get desired properties including precise residual solvent, moisture level, particle morphology, as well as density and size of particulates, which is crucial in the pharmaceutical industry. With high-performance spray dryers like the Yamato DL410 Large Capacity Spray Dryer, you can produce fine particles with sizes from 10 to 100 micrometers, which are considered by many to be difficult to achieve.

Furthermore, you are guaranteed a contaminant free powder with minimal moisture and zero oxidation, so you can guarantee patrons that your products are safe.

Industrial Products

Aside from food and pharmaceutical production, spray dryers are essential for the industrial creation of powdered materials such as catalyst supports, ceramic materials, microalgae, detergents, and paint pigments.

Used, basically, for encapsulation by most industries, applications of spray drying equipment in an industrial setting includes the production of not just powders but also textiles, adhesives, pesticides, carbonless copy paper, and anti-corrosive coatings just to mention a few. The microencapsulation technique involves the use of coatings such as polyvinyl alcohol, sodium alginate, starch, and gelatin.

By encapsulating, you get to reap numerous benefits; one is an extended shelf life for your product and another is increased stability. On the other hand, you also get to decrease the evaporation of the volatile core in products such as paints and pesticides. Aside from those, you also get to reduce oxygenation, prevent a chemical reaction, and improve handling properties of adhesives.

Now, if you are spraying acidic samples for either aqueous or organic solvent, before exhausting to environment or recirculating to the GAS410 Solvent Recovery Unit, we recommend using the GWS410 Organic Solvent Washing Unit to neutralize the air or gas which contains acidic ingredients.

Products

|

|

|

|

|

|

|

|