Stop spinning in circles

You probably call them rotovaps in your lab. And you know rotary evaporators are extremely valuable to lots of downstream applications requiring efficient distillation and solvent removal.

Rotary evaporators remove solvents from samples through evaporation.

You reduce the pressure within the system to lower the solvent boiling point, rotate the sample to increase the effective surface area, and heat up the sample.

Because of this technique’s distillation efficiency, most users prefer rotary evaporators over standard distillation systems. Not to mention, rotary evaporators ensure samples receive more even and consistent heating from a heated liquid without overheating the samples.

But did you know that most rotary evaporators aren’t built for R&D?

They’re built to follow a pre-determined method. Not to develop your own.

So, if you’re doing R&D and looking for a rotary evaporator that’s suitable for method development, how do you separate appropriate from not?

There are a handful of factors you can look at.

- Rotation speed range

- Programmability

- Footprint

- Price

This guide contains everything you need to know so your lab makes an appropriate choice that helps control costs and develop new, innovative processes other labs can’t.

Why rotation speed range matters

Most rotary evaporators feature rotation speed ranges around 10 or 20 rpms to 270 or 280 rpms.

It’s almost an arbitrary limit. And it doesn’t allow users to experiment with the full range of settings an application might benefit from.

To do innovative work in your R&D lab, you need as wide a range of rotation speeds as possible.

You can learn more about the RE202/212 mini rotary evaporator for R&D here.

How programmability impacts R&D

You start your distillation with a liquid.

Maybe your process distills down to a large chunk of solid material in the flask, which you break into pieces to remove from the flask. And you further crush the chunks into granules or powder for the next step in your process.

When your rotary evaporator can be programmed to speed up, change directions, and run a complex SOP, you can actually automate the granulation in the flask.

So you can set your rotovap to spin at, say, 315 rpms for 30 minutes.

Then slow down to 10 rpms backwards for 20 seconds, 10 rpms forwards for 20 seconds. Repeating for 20 minutes. Then a final circuit of 5 rpm rotations for a minute.

The speed and direction changes give you a granulated solid, closer to a powder than anything else. And save you or your technician the time it takes to break down the solid manually.

This kind of programmability usually comes with a high pricetag. And if you’re doing R&D you’re under a lot of pressure to control costs.

Look for a challenger brand that will give you better value than the big names. You’ll get the programmability you want for up to 20% less.

Start your search with a quote Yamato R&D mini rotary evaporator.

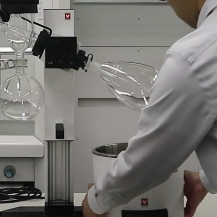

Rotary evaporator components that matter to you

They’re probably shy to ask about the basics. But you need them to know the basic parts of the rotary evaporator they’ll be working with.

Your basic rotary evaporator setup includes:

- Rotary motor

- Receiving flask

- Heating bath

- Condenser

- Trap ball

You can also mix and match the rotary evaporator with different systems like water circulators, solvent recovery units, and more depending on your intended use.

- The rotary motor rotates the evaporation flask or vial containing the sample. A brushless motor will cost you less in repairs and generally lasts longer than any other option.

- A water, oil, or bead bath heats the sample evenly while it spins.

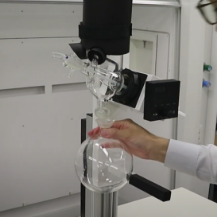

Condensers come in three different configurations:

- The traditional glass set where condenser is tilted diagonally

- The standard glass set where condenser is set vertically, suitable for limited space

- The dry-ice vertical condenser, also known as cold finger condenser, suitable for volatile or low boiling points solvents.

- A vacuum source should be connected to reduce the pressure in the instrument, allowing samples to boil at a lower temperature.

The receiving flask at the bottom of the condenser catches the solvent after it re-condenses.

The quality of the glassware set is important for equipment safety and lifespan. Better glass lasts longer. And it’s worth investing in.

What will a manufacturer ask before recommending a model?

1. What sample type do you work with?

As with any lab instrument, completely understanding the sample types you work with plays a significant role in the right configuration for your rotary evaporator.

The solvents you commonly work with, for example, greatly impact the kind of vacuum pump to use with the system.

Information about your samples will help a manu9facturer make an appropriate recommendation.

2. What’s your required rotation speed?

Faster rotation encourages quicker evaporation, as it increases surface area of the sample.

A wide range of rotation speeds lets you test new methods and improve your processes.

If your SOPs are already well established, a model like Yamato’s RE801 & RE601 or RE301 rotate from 20 to 250 rpms.

Yamato’s RE202/212 mini rotary evaporator is the market leader in rotation speed with its 5 to 315 rpm range.

Aside from rotation speed, rotavaps also feature different rotation modes.

Yamato’s RE202/212 features reverse rotation mode and auto inversion to help reduce hands-on time in the powder drying process (see How programmability impacts R&D on page 3).

3. What’s the volume of your application?

Once you have an idea of what your expected throughput may be, you can determine the flask size and water bath capacity you need and find out which rotary evaporator can support these.

If you’re working in R&D, most of your samples will be best suited for 100ml to 2L rotary evaporator flasks.

And don’t forget to consider the space you have for your rotary evaporator before you buy. A small footprint is invaluable in most labs. Don’t assume you can Tetris your rotovap into any available space.

Yamato Scientific was the first rotovap manufacturer to introduce the set inversion function in the RE202/212 series, where glassware and bath can be set on either side, left or right, depending on installation location and user’s dominant hand.

4. Do your operators have large muscles?

Rotary evaporators with automated lifts are ideal for continuous workflow while manual lifts offer durability to withstand everyday lab use and are easy to maintain.

However, manually adjusting the lift can be time consuming and are not recommended for large volume workloads. It tires operators out.

Yamato’s RE202/212 offers manual lifting as a more cost-effective option while the RE301/601/801 rotary evaporators are constructed with a motorized lift to easily raise and lower the lift by a simple switch operation.

5. What condenser do you currently use?

The choice between condenser types largely depends on your intended use and the space you have. You can find models with available glassware configurations in diagonal or vertical orientation, or even one with a cold finger configuration.

A diagonal glass condenser is a common choice for standard distillation of samples.

Vertically set condensers are ideal for distillation of samples with higher boiling points. This is also a great choice for users who have limited bench space.

You also have the option of a vertically set cold finger glass condenser for use with ice or dry ice for volatile or low boiling points. This vertically oriented cold finger condenser provides a cooling solution without the necessity for a constant supply of cooling water.

It’s common for the production of tinctures, yielding a thick, highly-pure concentrate with relatively little solvent use. A cold finger condenser is common in educational institutions where use is seasonal and where they prefer to avoid the hassle of cooling hose set-up.

All condenser configurations are available at Yamato Scientific.

6. What temperature range do you work within?

The rotary evaporator’s water bath temperature capacity is also an important part of your setup.

A quick review of your SOP should give you the range you need. At Yamato, you can choose from water baths with temperature capacities ranging from room temp +5 to 95°C.

To give you an idea as to which rotary evaporator would be compatible with your temperature preferences, Yamato’s RE301 digital rotary evaporator and RE601/801 are compatible with the BM500/510 water bath system with temperature capacities of RT +5°C~90°C.

The RE202/RE212 mini rotary evaporator for R&D is compatible with BM302 and BM312 water baths with a temperature range of RT+10 to 90°C.

If you are leaning towards higher temperature capacities, consider getting oil baths as these were made to withstand higher temperature ranges than water baths. Check out Yamato’s BO302, BO312, BO400, BO410, and BO601 oil bath models, which are all capable of heating up to 180°C.

What peripherals do you need?

Get all the peripherals you can from the same manufacturer. There will be design quirks that impact your application if you get a rotary evaporator from Brand Y, but a vacuum pump from Brand Z.

A. Water Bath

You know a rotary evaporator needs a water bath to keep solvents from freezing during the evaporation process. So aside from choosing the right rotary evaporator, you also need a compatible water bath to come along with your purchase.

Some models are designed with removable water tanks while others are flat shaped baths for convenient cleaning.

When choosing, make sure to opt for a bath that has a temperature capacity that won’t exceed your solvent’s boiling point.

B. Vacuum Pump

A vacuum pump allows you to lower the pressure within the rotary evaporator. The rotary evaporator’s vacuum controller works together with the pump so you can preset a specific pressure. If you’re looking for vacuum pumps, Yamato recommends the ULVAC DTC and KNF N820G diaphragm type dry vacuum pump.

C. Water Recirculating Chillers

Most consider installing chillers for better temperature accuracy and convenience.

It’s a way to make the conditions in your distillation more consistent.

These units are more efficient in cooling and do not require constant refilling of dry ice or water and are more environment friendly. Yamato’s CF301 and 800 water circulators (chillers), in 4L and 16L capacity respectively, provide powerful cooling capacity.

When using the CF800 model, up to 4 rotary evaporators can be connected.

D. Solvent Recovery Unit

The solvent recovery unit collects organic solvent substances from vapor sucked in by the vacuum pump during evaporation.

It prevents discharge of dangerous organic solvents into the air.

Yamato’s RT200 organic solvent recovery unit is designed with a hard glass condenser and a 500 ml solvent collecting flask.

E. Additional Glassware

Apart from the glassware set that comes with your initial purchase, you can add additional evaporating flasks, receiving flasks, joints, trap balls, and other glassware to your quote.

Yamato offers 100mL to 2L evaporating and receiving flasks.

Made to order safety-coated glassware is also available.

What are your next steps?

Get a quote.

Get a few, actually.

Start with a quote from Yamato Scientific.

Chances are it’ll be 15% better than any other manufacturer with similar features and quality (premium).

When you’re ready, contact us at 1-800-292-6286 or email [email protected].